Excitement About Overland Conveyors

Table of ContentsThe Main Principles Of Overland Conveyors Top Guidelines Of Overland ConveyorsA Biased View of Overland ConveyorsThe 10-Minute Rule for Overland ConveyorsRumored Buzz on Overland ConveyorsThings about Overland ConveyorsOverland Conveyors Fundamentals Explained3 Easy Facts About Overland Conveyors Described

There are additionally various other associated devices that utilize a chain to drag things such as a tubular drag conveyor. As NC State College discusses, "Sortation conveyors are made use of for combining, identifying, swearing in, as well as dividing items to be communicated to certain destinations." They make use of various approaches to sort incoming plans. These conveyors make use of a vacuum cleaner or air pressure to relocate product.These are similar to a roller conveyor other than with small, individual wheels instead of long, cylindrical rollers. Strolling Light beam conveyors move material incrementally along the conveyor making use of relocating and static assistances.

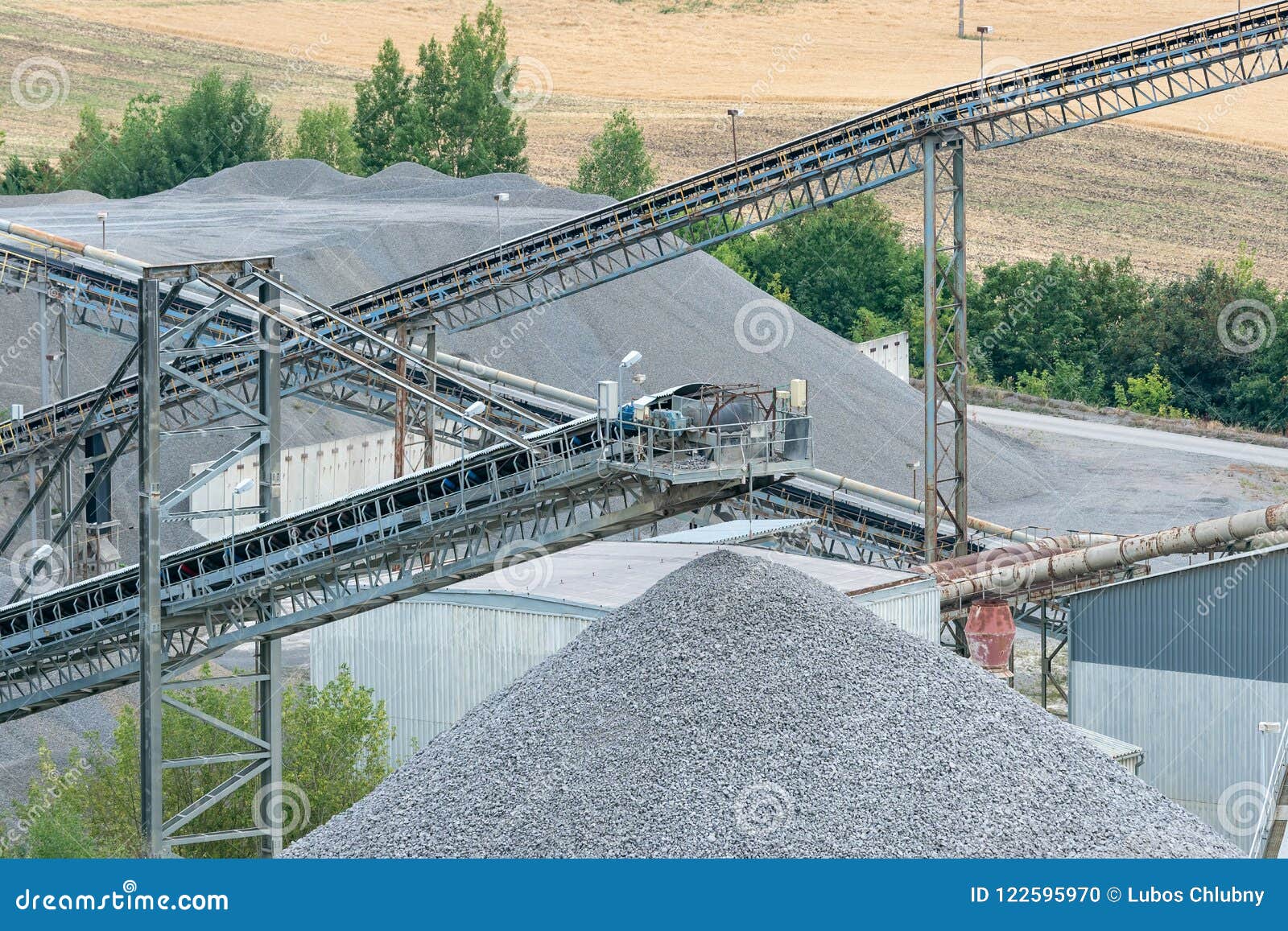

The conveyor belting is sustained by either a steel slider frying pan for light tons where no friction would certainly be put on the belt to cause drag or on rollers. Power is given by electric motors that utilize either variable or consistent speed reduction gears. The belts themselves can be made from many materials, which must represent the conditions under which the belt will be operating.

Moving a much heavier load means a thicker and also stronger construction of conveyor belting product is needed. Belt conveyors are usually powered and can be run at numerous rates depending upon the throughput called for. The conveyors can be run flat or can be inclined also. Belt conveyors can be troughed for bulk or huge materials.

The 45-Second Trick For Overland Conveyors

Key specs consist of the roller size and axle facility measurements. The rollers are not powered and use gravity, if inclined, to relocate the item, or manually if mounted flat.

Numerous sizes as well as tons carrying capacities are available. Ball transfer conveyors are not powered and rely on external pressures to relocate the item along the conveyor. Magnetic Magnetic Conveyors make use of relocating magnets placed beneath fixed plates, tables, or various other kinds of non-magnetic slider beds, to relocate magnetic (ferrous) products, typically in the kind of machining scrap.

Secret specifications consist of the chute material as well as the physical measurements such as size and also chute size. Chute conveyors are used for scrap handling, product packaging, postal service plan or mail handling, and so on.

Indicators on Overland Conveyors You Should Know

Chain/Tow/Drag Line Conveyor Drag/Chain/Tow Conveyors use mechanical tools affixed to moving participants, usually chains or cables, to drag or tow products. Drag conveyors are made use of for moving bulk materials in containers, flights, or various other attachments and can have numerous discharge or filling points. Tubular drag conveyors utilize a fully confined system of chains to share product in any instructions.

Tow conveyors make use of a towline such as cable televisions or chains, normally in the flooring or just above it, to tow item straight or to tow rolled carts or dollies. Overhead Expenses Conveyors are placed from ceilings that utilize trolleys or carriers relocated by chains, wires, or similar connections. Expenses conveyors are mainly utilized in material handling applications where the product needs to be hung, such as dry-cleaning garment lines, paint look at here lines, or components managing systems, or for cooling down and curing.

Products for the conveyors can be metallic or non-metallic depending on the media being communicated. Various sizes are readily available depending on the tons and throughput requirements. A screw conveyor in a vineyard presses grapes to the press.

7 Easy Facts About Overland Conveyors Shown

The helical screw features within a housing, trough or area to maximize the rotational pressure. Producers utilize screw conveyors to deliver products such as flakes, grains, powders, seeds, and also granules. These tools can be used to blend, perturb or blend such products, or to maintain options.

Base conveyors utilize several screws in an open trough. Centerless, or shaftless, screw conveyors do not have a main shaft and also instead contain a vacant helix. This layout still moves the substrate but enables for even more flexibility within the case. Materials can be metal or non-metal relying on the media being communicated.

The product being supported at a fixed position is gotten by the walking light beam and also indexed to its next placement, where another production step takes location. This activity repeats over the size of the conveyor. Strolling beam conveyors can have single or numerous lines relying on the product. Wheel Conveyor Wheel Conveyors use unpowered wheels to relocate things along their lengths by gravity or hands-on power.

The Of Overland Conveyors

The composition of the material, if powders, granules, pellets, fibers, or flakes are being communicated, need to likewise be taken into consideration, in addition to the particle dimension, weight, as well as density. The function of the conveyor system itself might vary. The two primary categories of relocating material with a process are conveying as well as feeding.

The preferred window of time for this activity should be considered, as well as the amount of pick-up and also decline points, the amount of material being moved, and whether or not cross-contamination between several products is a problem. Feeding is more time sensitive and also requires much more accurate systems than coveying.

The product being relocated might need to be supplied in sets, or at a regulated, constant price. An important factor to take into consideration before the selection of a conveyor system is the atmosphere in which it will be made use of. High humidity, temperature, vibration, stress, delicate or harmful materials, and also combustible This Site items in the facility ought to all be reviewed with a conveyor producer to figure out any kind of possible risks and also the countermeasures and workarounds required.

Overland Conveyors - The Facts

Conveyors systems are usually relatively intricate in their style and building due to their big ranges and integration right into different manufacturing facility processes. Still, the modular nature of several conveyor components makes even long and intricate click here now systems conveniently possible. Producers of such systems can provide layout aid to ensure that the conveyor suits the office.

Belt conveyors, for example, come in a variety of sizes as well as can range from foot-long units used on product packaging lines to mile-long systems used for mining operations. Conveyors can be hand poweredwhere items are relocated along by hand over rollers or wheelsor engine/motor powered, or gravity powered. In general, however, they are driven by AC and DC motors, either directly or with reduction equipments, chains, and sprockets, and so on.

Fascination About Overland Conveyors

Handbook type roller and wheel conveyors can commonly be acquired in distinct areas as well as bolted approximately form product dealing with systems of virtually any type of size. As a whole, powered conveyors use head shafts as well as tail shafts where the head end offers the drive arrangement, as well as the tail end provides for adjustment of the chain or belt stress.

of ac electric motors. Long belt conveyors transporting ore as well as other products typically count on conveyor belt idlers to create troughs in the belts to much better have the conveyed products. Conveyor Solution - A Recap This guide gives a basic understanding of conveyor system ranges, factors to consider for usage, their applications, and commercial usages.